Hands-On Training for Tomorrow’s Industry Leaders

An apprenticeship at a metalworking company provides you on-the-job training where you earn while you learn. We believe in the power of hands-on learning to launch successful careers in the metallurgical engineering and trades sectors. Our apprenticeship component is designed to bridge the gap between theoretical knowledge and practical expertise, providing participants with an immersive experience that prepares them for the demands and opportunities of the casting and forging industries. METAL can help your company develop an apprenticeship program for roles such as forging operator, die setter, mold maker, core maker, CNC operator, maintenance technician, and more.

Nearly 3,000 manufacturers across the country now offer apprenticeships, recognizing it as a proven solution for recruiting, training, and retaining world-class manufacturing talent in good, quality jobs.

Wage increases for apprentices are tied to skill gains, allowing them to earn more while advancing their careers. Upon completing the apprenticeship, participants receive a national credential from the U.S. Department of Labor and may earn industry-recognized credentials and credit toward an associate degree. METAL’s apprenticeship program can help companies:

- Train employees for higher-skilled positions

- Develop career paths to attract talent

- Provide pathways for career advancement

- Standardize training across company sites

- Improve productivity, safety practices, and company capacity

- Develop a learning culture that boosts loyalty and retention

We provide:

- Consulting services to help your company develop and implement an apprenticeship program

- Customizable apprenticeship templates with related training and on-the-job competencies to jump start your programs

- Connections to funding resources to help build and sustain your program

- Training experts to customize your program based on your processes, equipment and products

- Access to free online training modules to supplement your internal training plan

METAL partners with Jobs for the Future for its apprenticeship program. For information on how to provide apprenticeship opportunities at your company, contact METAL Workforce Manager Lucinda Curry through our contact form.

Watch our webinar:

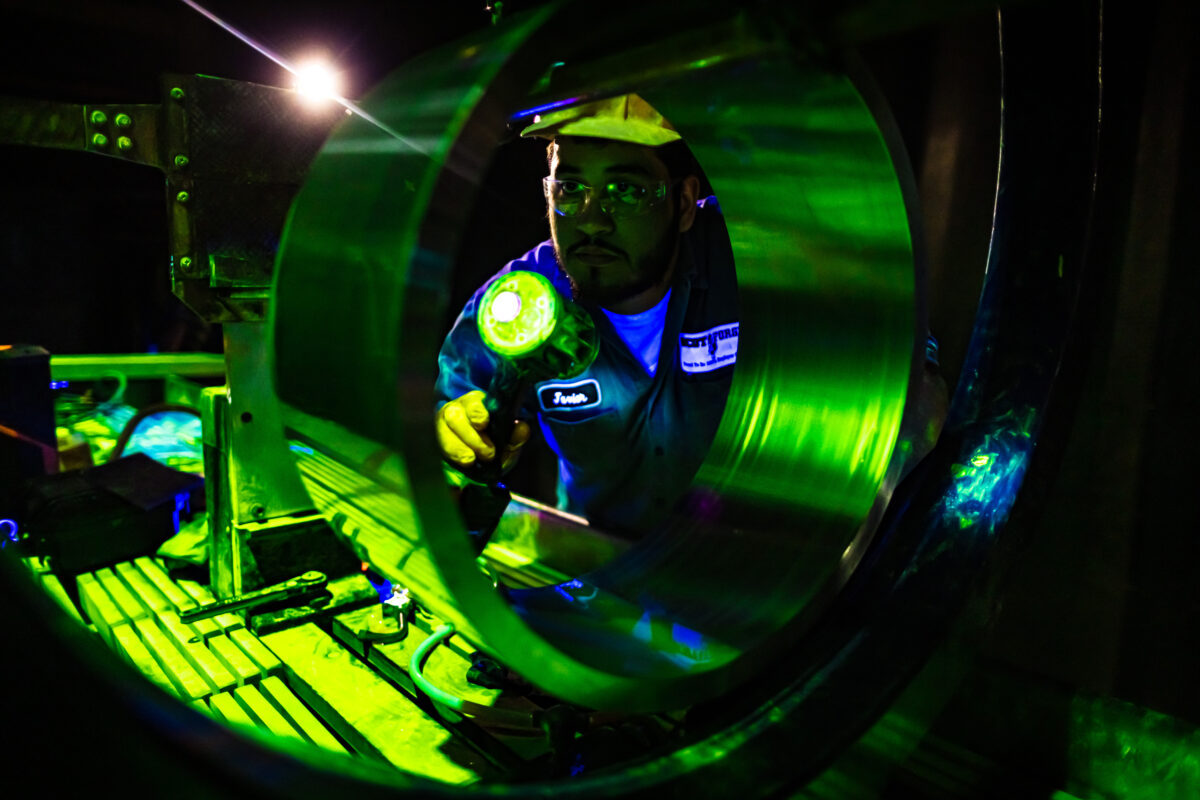

Real-World Experience

METAL apprenticeships offer a direct pathway into the workforce, allowing participants to apply their classroom knowledge in real-world settings. Apprentices work alongside seasoned professionals at leading foundries and metalworking facilities across the nation, gaining firsthand experience and valuable insights into the day-to-day operations and challenges of the industry.

Skill Development

Through the apprenticeship program, participants develop a robust set of skills that are crucial for their professional growth and advancement in the industry. These skills include not only the technical aspects of metallurgy, such as metal casting and forging techniques, but also critical thinking, problem-solving, and teamwork—competencies that are highly valued in any career path.

Career Advancement

Apprenticeships not only equip participants with the skills needed to excel in their initial positions but also lays the foundation for future advancement. By the end of the program, apprentices are well-prepared to take on more complex roles, contributing significantly to their workplaces and the broader industry.