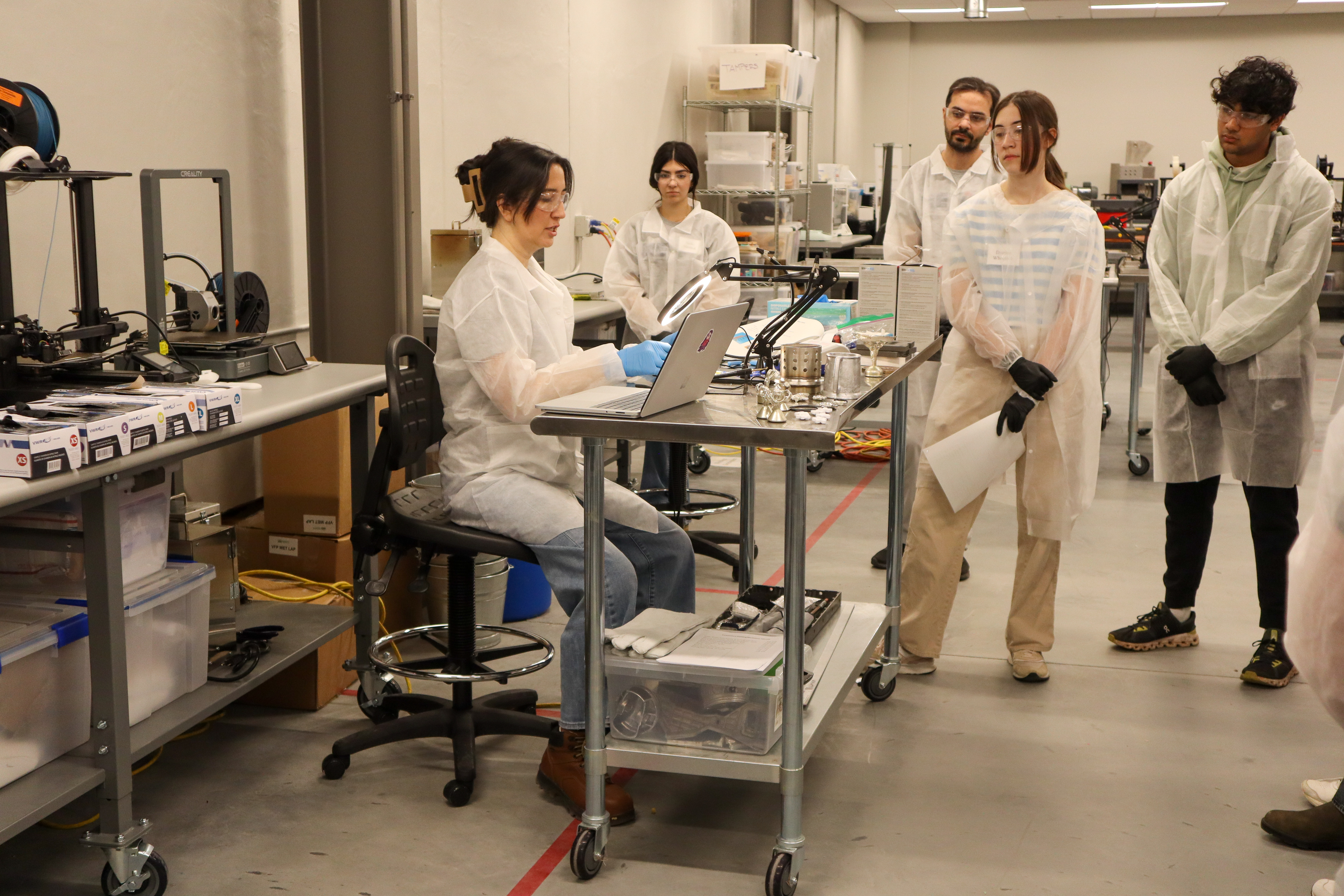

The University of Tennessee at Knoxville (UTK) hosted an investment casting workshop in early March to introduce high school students to careers in metallurgy.

The University of Tennessee at Knoxville (UTK) hosted an investment casting workshop in early March to introduce high school students to careers in metallurgy.

The workshop was a part of the university’s partnership with METAL (Metallurgical Engineering Trades Apprenticeships & Learning).

Led by IACMI – the Composites Institute® with support from the Defense Department’s Innovation Capability and Modernization (ICAM) Office, METAL strengthens and diversifies the U.S. metal manufacturing workforce, focusing on casting, forging, and plate rolling.

The investment casting workshop provided a hands-on introduction to metallurgy, allowing students to explore, experiment and consider a future in this essential field.

The Process of Investment Casting

Investment casting is a process that allows students to create metal objects from scratch.

The process begins with creating a pattern of the final object, which students can 3D print, injection mold, or carve by hand. The pattern is attached to a wax sprue, forming a network for molten metal. The pattern and sprue are then coated in a ceramic slurry. After hardening – which takes a few hours to several days depending on size – students place the ceramic-coated patterns in a high-temperature oven.

Over about 13 hours, the temperature gradually rises to nearly 1400 degrees Fahrenheit, melting and burning away the wax to leave a precise mold. Typically a multi-day process, this process was condensed to fit the five-hour workshop, thanks to instructor preparation.

Once the mold is ready, participants heat tin until it becomes liquid and pour it into the ceramic mold. METAL workshops use tin because of its low melting point and relative safety in a student learning environment. After cooling, the ceramic shell is dissolved, revealing the metal casting. Students refine their pieces by cutting excess material, filing edges and smoothing surfaces.

“They get to leave with something that they’ve created with their own two hands,” said Amy Wheelock, research assistant at the University of Tennessee Tickle College of Engineering’s Fibers and Composites Manufacturing Facility. “Right now, we’re doing everything from rings to keychains.”

The Importance of Hands-On Manufacturing Education

Manufacturing plays a crucial role in the global economy and workforce, contributing to large-scale industries like aerospace and automotive manufacturing.

Exposing students to activities like investment casting provides valuable experience with industry-standard manufacturing techniques, giving students an advantage when they begin looking for jobs.

Understanding manufacturing techniques is also essential for engineers who must be knowledgeable about the materials and production methods used in various industries. Additionally, investment casting introduces students to skills applicable in various STEM careers.

Even for students who may not pursue a direct career in manufacturing or engineering, learning investment casting can be beneficial in fields such as dentistry and jewelry making. More than just a techni

cal skill, investment casting fosters creativity, problem-solving and a deeper appreciation for the role of manufacturing in everyday life.

A Hands-On Learning Experience

Investment casting is just one of the many techniques METAL workshops cover to introduce students to casting, forging, manufacturing and design.

Engaging students in these hands-on manufacturing processes fosters an understanding of traditional metalworking techniques.

The ability to transform an idea into a tangible object provides both practical skills and a sense of accomplishment.

Stay tuned for more workshops and opportunities to get involved in the world of metals! If you’re interested in learning more or hosting your own workshop,contact us here: https://www.metalforamerica.org/contact-us/

About IACMI:

IACMI-The Composites Institute® is a 170-plus member community of industry, colleges and universities, national laboratories, and government agencies working together to benefit the nation’s energy, manufacturing, and economic security. IACMI is managed by the Collaborative Composite Solutions Corporation (CCS), a not-for-profit organization established by The University of Tennessee Research Foundation. A Manufacturing USA institute, IACMI is supported by the U.S. Department of Energy’s Advanced Materials Manufacturing Technologies Office, as well as key state and industry partners.